Diecasting: The Spine of Precision Manufacturing

Diecasting: The Spine of Precision Manufacturing

Blog Article

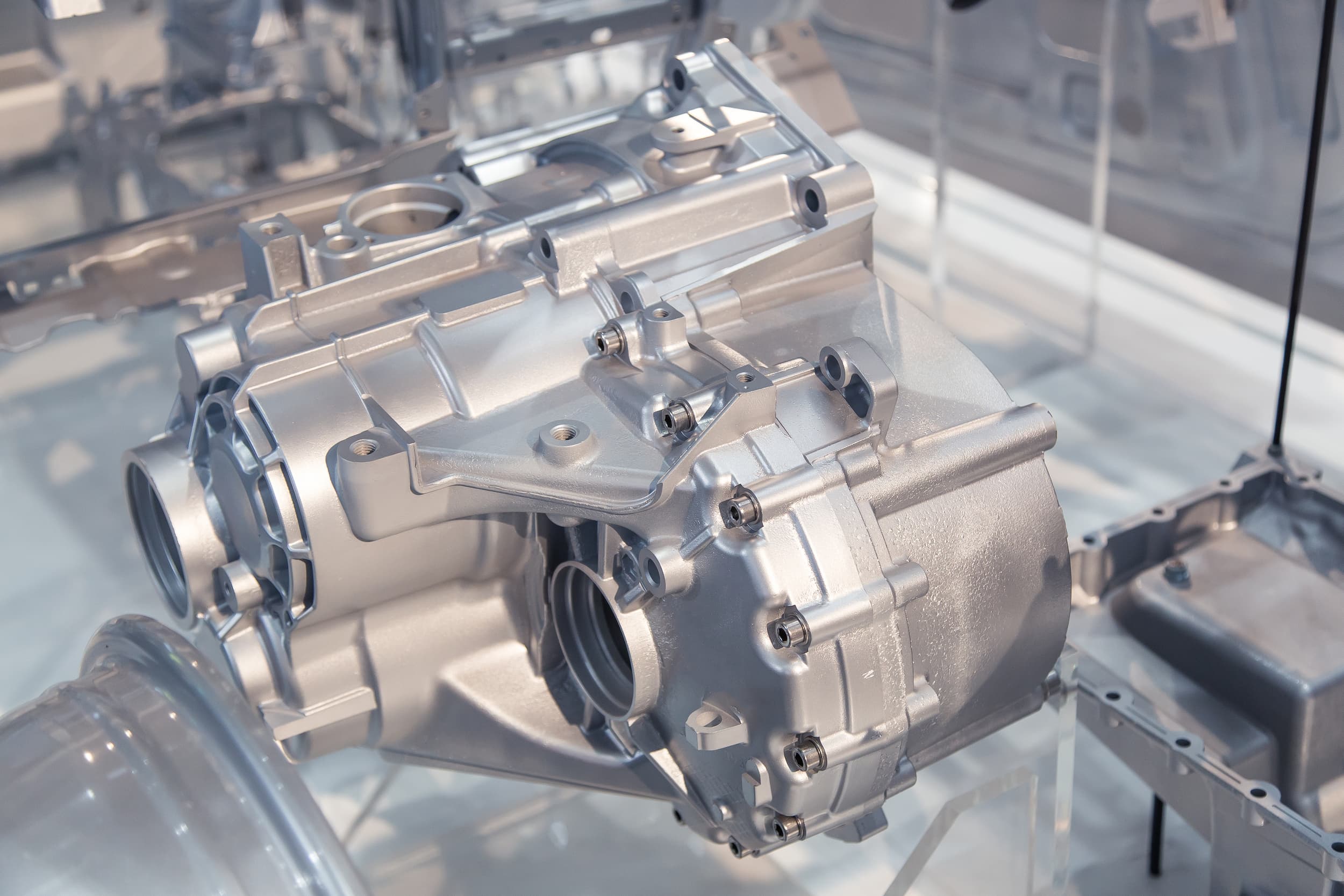

Diecasting is an important manufacturing method that involves pushing the molten metal to a mold cavity with high pressure. This technique is renowned for its capability to create complicated shapes and designs with a high degree of accuracy and repeatability, making it indispensable in various sectors. From aerospace and automotive all the way to household appliances and consumer electronics Diecasting plays an essential part in constructing components that comply with strict specifications for quality and efficiency. This article will explore the intricacies of diecasting, highlighting its advantages, processes and uses.

In the center of diecasting is the mold, known as a"die" that is carefully designed and constructed from solid steel, which is hardened to resist the harsh conditions that are encountered during this casting. Die design is crucial, as it needs to be able to handle the molten metal's flow and solidification while making sure that the tolerances are tight to assure the highest level of precision. The process of casting dies the metals like aluminum, zinc, magnesium and copper are heated until they are molten. The molten material is placed into the mold cavity at high pressure, filling every crevice and crevice of the mold. The rapid cooling and formation of solidified metal results in components that have exceptional dimensional accuracy as well as a polished surface, typically without the need for further machining or finishing processes.

One of the main benefits of diecasting is its ability to create parts that have high precision in dimensional measurement and smooth surface surfaces. High-pressure injection makes sure that the molten metal conforms precisely to molds, resulting in components that need minimal removal or finishing. This kind of precision is ideal in the production of complex geometries as well as thin-walled segments that are difficult to create or not possible through other manufacturing techniques. Diecasting also produces pieces with tight tolerances as well as exceptional repeatability. This makes it perfect for large-scale production. The efficiency of the process will also lead to savings in costs due to the fact that high production rates reduce labor costs and material waste.

Diecasting also offers considerable benefits with regard to physical properties and efficiency. Diecast components are known for their toughness and durability, which are essential qualities for parts that are used in demanding applications. Fine-grain formation that occurs during the rapid cooling of the metal helps to create the desirable characteristics, which makes diecast parts suitable for use in environments with high stress. Additionally, diecasting permits the integration of thin walls as well as complex components without harming the strength of the finished product. This capability is particularly advantageous in the automotive and aerospace industries, where weight reduction and retaining structural strength can be crucial to boost energy efficiency and overall efficiency. To obtain additional details kindly visit www.senadiecasting.com.my/

Diecasting's materials can play an important role in the final properties and functionality of the finished product. Aluminum is among the most widely used components due to its high strength-to-weight ratio, its resistance to corrosion and good thermal and electrical conductivity. Zinc alloys are also very popular for their durability, strength, and the ability to produce components with fine specifics. Magnesium alloys benefit from the advantages that they are the tiniest structure metal. They are perfect for use in areas where weight reduction is crucial. Copper alloys are less common, are used for their superior electro-conductive properties and corrosion resistance. The material selection depends on the particular requirements of the application, including their mechanical properties, the climate conditions, as well as cost issues.

Diecasting represents a pinnacle of manufacturing technology, offering a blend of precision, productivity, and versatility that's unmatched by other methods. Its ability to make complicated, high-end parts that possess outstanding mechanical properties make it a necessity in a variety of industries, from automotive to consumer electronic products. The effectiveness and savings in material inherent in the diecasting process underscore its value in high-volume manufacturing. Its flexibility guarantees that it is able to accommodate the evolving demands of modern manufacturing. While industries push the boundaries of innovation and performance, diecasting will be a vital tool helping to advance technology and facilitate the production of cutting-edge products that will shape our future.